Nanofiber Weaving Technologies in 2025: Unraveling the Next Wave of High-Performance Materials. Explore How Cutting-Edge Weaving Innovations Are Shaping the Future of Textiles, Filtration, and Medical Devices.

- Executive Summary: Key Insights and Market Highlights for 2025–2030

- Market Overview: Defining Nanofiber Weaving Technologies and Their Applications

- Market Size & Forecast (2025–2030): Growth Drivers, Trends, and 18% CAGR Analysis

- Competitive Landscape: Leading Players, Startups, and Strategic Alliances

- Technological Innovations: Breakthroughs in Nanofiber Weaving Methods and Machinery

- Application Deep Dive: Textiles, Filtration, Medical Devices, and Emerging Sectors

- Regional Analysis: North America, Europe, Asia-Pacific, and Rest of World

- Investment & Funding Trends: Venture Capital, M&A, and Government Initiatives

- Challenges & Barriers: Technical, Regulatory, and Supply Chain Considerations

- Future Outlook: Disruptive Opportunities and Strategic Recommendations for Stakeholders

- Sources & References

Executive Summary: Key Insights and Market Highlights for 2025–2030

The period from 2025 to 2030 is poised to witness significant advancements in nanofiber weaving technologies, driven by escalating demand across sectors such as healthcare, filtration, energy, and smart textiles. Nanofiber weaving, which involves the precise arrangement of fibers with diameters in the nanometer range, is enabling the creation of materials with superior mechanical strength, flexibility, and functional properties. The market is expected to experience robust growth, underpinned by ongoing innovations in electrospinning, melt-blowing, and solution spinning techniques.

Key insights for this period highlight the increasing integration of nanofiber-based materials in medical applications, particularly for wound dressings, tissue engineering scaffolds, and drug delivery systems. Companies such as Freudenberg Group and Ahlstrom are expanding their nanofiber product portfolios to address the stringent requirements of the healthcare sector. In parallel, the filtration industry is leveraging nanofiber weaves for high-efficiency air and liquid filtration, with Hollingsworth & Vose and Toray Industries, Inc. at the forefront of commercial deployment.

The energy sector is another major beneficiary, as nanofiber weaving technologies contribute to the development of advanced battery separators, fuel cell membranes, and lightweight composites. Strategic collaborations between material science companies and research institutions are accelerating the commercialization of these innovations. Furthermore, the emergence of smart textiles—integrating sensors and conductive nanofibers—signals new opportunities for wearable technology, with Teijin Limited and DuPont investing in R&D to capture this growing market.

From a regional perspective, Asia-Pacific is anticipated to lead market growth, supported by strong manufacturing capabilities and government initiatives promoting advanced materials. Europe and North America are also expected to maintain significant market shares, driven by regulatory support and a focus on sustainable, high-performance materials.

In summary, the 2025–2030 outlook for nanofiber weaving technologies is characterized by rapid technological progress, expanding end-use applications, and intensifying competition among key players. Companies that prioritize innovation, scalability, and sustainability are likely to secure a competitive edge in this dynamic market landscape.

Market Overview: Defining Nanofiber Weaving Technologies and Their Applications

Nanofiber weaving technologies represent a rapidly evolving segment within advanced materials engineering, focusing on the fabrication and integration of fibers with diameters typically below 100 nanometers. These technologies enable the creation of highly porous, lightweight, and mechanically robust materials with unique surface area-to-volume ratios, making them suitable for a wide array of high-performance applications. The market for nanofiber weaving is driven by ongoing innovations in manufacturing processes, such as electrospinning, solution blowing, and centrifugal spinning, which allow for precise control over fiber morphology and alignment.

Key applications of nanofiber weaving technologies span several industries. In healthcare, nanofiber-based scaffolds are increasingly used for tissue engineering, wound dressings, and drug delivery systems due to their biocompatibility and ability to mimic natural extracellular matrices. Companies like Johnson & Johnson and Medtronic are exploring nanofiber materials for next-generation medical devices and implants. In filtration, nanofiber membranes offer superior efficiency in air and liquid filtration, capturing ultrafine particles and pathogens, which is particularly relevant for personal protective equipment and industrial filtration systems. 3M and Donaldson Company, Inc. are notable players leveraging nanofiber technologies in this sector.

The textile industry is also witnessing the integration of nanofiber weaving for the development of smart fabrics and high-performance apparel, offering enhanced breathability, moisture management, and antimicrobial properties. Toray Industries, Inc. and Teijin Limited are at the forefront of incorporating nanofiber technologies into functional textiles. Additionally, the energy sector benefits from nanofiber-based separators and electrodes in batteries and fuel cells, with companies like Samsung Electronics investing in research for improved energy storage solutions.

As of 2025, the global market for nanofiber weaving technologies is characterized by robust research and development activity, strategic collaborations, and increasing commercialization across diverse end-use industries. Regulatory support and growing awareness of the environmental and performance advantages of nanofiber materials are expected to further accelerate market growth, positioning nanofiber weaving as a cornerstone technology in the next generation of advanced materials.

Market Size & Forecast (2025–2030): Growth Drivers, Trends, and 18% CAGR Analysis

The global market for nanofiber weaving technologies is poised for robust expansion between 2025 and 2030, with projections indicating a compound annual growth rate (CAGR) of approximately 18%. This surge is driven by escalating demand across diverse sectors, including filtration, biomedical, energy storage, and advanced textiles. The unique properties of nanofibers—such as high surface area-to-volume ratio, tunable porosity, and superior mechanical strength—are catalyzing their adoption in next-generation products and applications.

Key growth drivers include the increasing need for high-performance filtration media in environmental and industrial settings, where nanofiber-based membranes offer enhanced efficiency in capturing fine particulates and pathogens. The healthcare sector is also a significant contributor, leveraging nanofiber scaffolds for tissue engineering, wound dressings, and drug delivery systems. The push for sustainable and lightweight materials in automotive and aerospace industries further amplifies market momentum, as nanofiber composites deliver improved strength-to-weight ratios and functional versatility.

Technological advancements are shaping market trends, with innovations in electrospinning, solution blowing, and centrifugal spinning enabling scalable and cost-effective nanofiber production. Companies such as Freudenberg Group and Auburn Manufacturing, Inc. are investing in R&D to refine weaving techniques and integrate nanofibers into commercial textile lines. Additionally, the emergence of smart textiles—incorporating sensors and conductive nanofibers—reflects a growing intersection with the electronics and wearables markets.

Geographically, Asia-Pacific is expected to dominate market share, propelled by rapid industrialization, expanding healthcare infrastructure, and strong government support for advanced materials research. North America and Europe are also witnessing significant investments, particularly in medical and environmental applications, with organizations like 3M and Donaldson Company, Inc. leading commercialization efforts.

Looking ahead, the nanofiber weaving technologies market is set to benefit from ongoing material innovations, regulatory support for clean technologies, and the integration of automation in manufacturing processes. The anticipated 18% CAGR underscores the sector’s dynamic growth trajectory, with new entrants and established players alike vying to capitalize on emerging opportunities across global value chains.

Competitive Landscape: Leading Players, Startups, and Strategic Alliances

The competitive landscape of nanofiber weaving technologies in 2025 is characterized by a dynamic mix of established industry leaders, innovative startups, and a growing number of strategic alliances. Major players such as Toray Industries, Inc. and Freudenberg Group continue to dominate the market, leveraging their extensive R&D capabilities and global manufacturing networks to advance nanofiber production and integration into textiles, filtration, and medical applications. These companies invest heavily in proprietary spinning and weaving techniques, focusing on scalability and product performance.

Startups are playing a pivotal role in driving innovation within the sector. Companies like Novatex Nanotechnology and Nanofiber Labs are developing novel electrospinning and solution-blowing methods, enabling the creation of highly uniform and functionalized nanofiber fabrics. These startups often collaborate with academic institutions and research organizations to accelerate the commercialization of their technologies, targeting niche markets such as smart textiles, advanced wound care, and high-efficiency air filtration.

Strategic alliances and joint ventures are increasingly shaping the competitive dynamics of the industry. For example, Toray Industries, Inc. has entered into partnerships with leading universities and technology firms to co-develop next-generation nanofiber weaving platforms, while Freudenberg Group has formed alliances with medical device manufacturers to integrate nanofiber materials into implantable products. These collaborations aim to pool expertise, share intellectual property, and accelerate time-to-market for new applications.

Industry bodies such as the Association of the Nonwoven Fabrics Industry (INDA) and the Textile Institute play a crucial role in fostering collaboration, setting standards, and promoting best practices across the nanofiber weaving ecosystem. Their initiatives help bridge the gap between research and industry, supporting both established companies and emerging startups.

Overall, the nanofiber weaving technology sector in 2025 is marked by rapid innovation, cross-sector partnerships, and a competitive drive to unlock new applications, with both incumbents and newcomers contributing to the field’s evolution.

Technological Innovations: Breakthroughs in Nanofiber Weaving Methods and Machinery

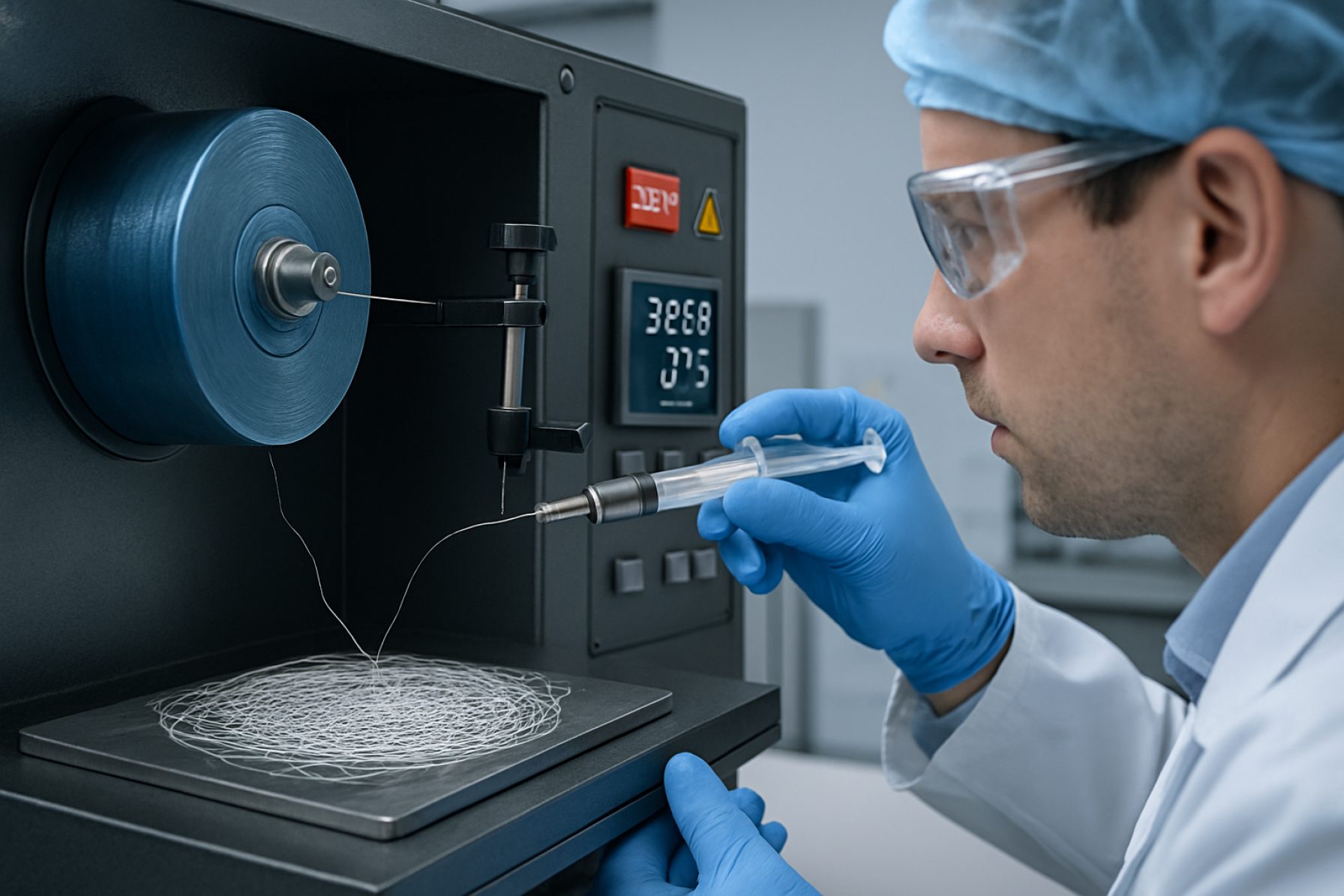

Recent years have witnessed significant breakthroughs in nanofiber weaving methods and machinery, fundamentally transforming the landscape of nanofiber-based textiles and composites. Traditional nanofiber production techniques, such as electrospinning, have been limited by low throughput and challenges in integrating nanofibers into complex woven structures. However, new technological innovations are addressing these limitations, enabling scalable, precise, and versatile nanofiber weaving.

One of the most notable advancements is the development of high-throughput electrospinning systems that can produce continuous nanofiber yarns suitable for weaving. Companies like Elmarco have introduced industrial-scale electrospinning machines capable of generating uniform nanofiber mats and yarns, which can be directly fed into automated weaving looms. These systems utilize multi-jet and needleless designs to increase production rates while maintaining fiber quality and consistency.

In parallel, robotic and computer-controlled weaving machinery has been adapted to handle the unique properties of nanofiber yarns. For example, Stäubli International AG has integrated advanced tension control and precision handling modules into their textile machinery, allowing for the delicate manipulation of nanofiber threads without breakage. This enables the creation of intricate woven structures with enhanced mechanical and functional properties.

Another breakthrough is the emergence of hybrid weaving techniques that combine nanofibers with conventional microfibers or filaments. This approach, pioneered by research collaborations with organizations such as Institut für Textiltechnik of RWTH Aachen University, leverages the strengths of both material scales, resulting in fabrics with superior filtration, strength, and flexibility. These hybrid methods often employ modified shuttle looms and jacquard machines equipped with specialized feeders and guides for nanofiber yarns.

Furthermore, real-time monitoring and quality control systems, incorporating machine vision and AI algorithms, are being integrated into nanofiber weaving lines. These systems, developed by companies like Uster Technologies AG, ensure uniformity and detect defects at the nanoscale, which is critical for high-performance applications in medical, filtration, and smart textiles.

Collectively, these technological innovations are propelling nanofiber weaving from laboratory-scale experiments to industrial-scale manufacturing, opening new possibilities for advanced materials and applications in 2025 and beyond.

Application Deep Dive: Textiles, Filtration, Medical Devices, and Emerging Sectors

Nanofiber weaving technologies have rapidly evolved, enabling the integration of ultra-fine fibers into a diverse array of applications. In the textile sector, nanofiber weaving is revolutionizing performance fabrics by imparting properties such as enhanced breathability, moisture management, and antimicrobial resistance. Companies like Toray Industries, Inc. are leveraging nanofiber webs to create lightweight, durable, and functional textiles for sportswear, protective clothing, and fashion, meeting the growing demand for smart and sustainable materials.

In filtration, nanofiber weaving allows for the production of membranes with precisely controlled pore sizes, significantly improving filtration efficiency for air, water, and industrial processes. Freudenberg Group and AAF International have developed nanofiber-based filter media that capture submicron particles, allergens, and pathogens, supporting applications in cleanrooms, HVAC systems, and automotive cabins. The fine structure of nanofibers increases surface area and reduces pressure drop, making these filters both effective and energy-efficient.

Medical devices represent another critical area where nanofiber weaving technologies are making an impact. Electrospun nanofiber scaffolds, for example, are being used in wound dressings, tissue engineering, and drug delivery systems. Smith+Nephew and 3M have introduced advanced wound care products utilizing nanofiber matrices that promote cell growth, manage exudate, and provide antimicrobial protection. The biocompatibility and tunable properties of nanofibers enable the design of medical devices tailored to specific clinical needs.

Emerging sectors are also exploring the potential of nanofiber weaving. In energy storage, nanofiber-based separators and electrodes are being developed to enhance the performance of batteries and supercapacitors. The electronics industry is investigating nanofiber mats for flexible sensors and wearable devices, while the construction sector is evaluating nanofiber-reinforced composites for improved strength and durability. Research institutions and companies such as DuPont are at the forefront of these innovations, driving the adoption of nanofiber weaving technologies across new markets.

As nanofiber weaving technologies mature, their versatility and performance advantages are expected to unlock further applications, supporting advancements in sustainability, health, and high-performance engineering.

Regional Analysis: North America, Europe, Asia-Pacific, and Rest of World

The regional landscape for nanofiber weaving technologies in 2025 reflects varying levels of technological advancement, market adoption, and research intensity across North America, Europe, Asia-Pacific, and the Rest of the World. Each region demonstrates unique drivers and challenges shaping the development and commercialization of nanofiber weaving solutions.

- North America: The United States leads in nanofiber weaving innovation, propelled by robust R&D investments and collaborations between academic institutions and industry. Organizations such as NASA and Oak Ridge National Laboratory are actively exploring nanofiber applications in aerospace, filtration, and biomedical sectors. The presence of advanced manufacturing infrastructure and a strong intellectual property regime further accelerates commercialization.

- Europe: Europe’s focus is on sustainable and high-performance materials, with the European Union funding initiatives under programs like Horizon Europe. Companies such as Freudenberg Group and research centers like Fraunhofer Society are at the forefront, particularly in automotive, healthcare, and environmental applications. Regulatory emphasis on eco-friendly production and circular economy principles is shaping the direction of nanofiber weaving technology development.

- Asia-Pacific: The Asia-Pacific region, led by Japan, China, and South Korea, is experiencing rapid growth in nanofiber weaving technologies. Japanese firms like Toray Industries, Inc. and Chinese companies such as Sinopec Group are scaling up production for use in electronics, filtration, and protective textiles. Government support, cost-effective manufacturing, and a large consumer base are key growth drivers, while regional collaborations foster innovation.

- Rest of World: In regions such as Latin America, the Middle East, and Africa, adoption of nanofiber weaving technologies is at an early stage. However, increasing awareness of advanced materials and growing investments in healthcare and water purification are expected to stimulate demand. Partnerships with global technology providers and pilot projects are gradually building local capabilities.

Overall, while North America and Europe emphasize innovation and sustainability, Asia-Pacific is characterized by rapid industrialization and market expansion. The Rest of the World is emerging as a potential growth area as awareness and infrastructure improve.

Investment & Funding Trends: Venture Capital, M&A, and Government Initiatives

The investment landscape for nanofiber weaving technologies in 2025 is characterized by a dynamic interplay of venture capital (VC), mergers and acquisitions (M&A), and robust government initiatives. As nanofiber applications expand across sectors such as filtration, biomedical devices, energy storage, and smart textiles, funding activity has intensified, reflecting both the technology’s maturation and its commercial promise.

Venture capital investment remains a primary driver of innovation in nanofiber weaving. Leading VC firms are increasingly targeting startups that demonstrate scalable manufacturing processes and novel applications. For example, companies leveraging advanced electrospinning and centrifugal spinning techniques have attracted multi-million dollar funding rounds, with investors seeking to capitalize on the growing demand for high-performance, sustainable materials. Notably, the focus has shifted from early-stage research to later-stage commercialization, as investors look for clear pathways to market and partnerships with established industry players.

Mergers and acquisitions are also shaping the competitive landscape. Larger materials and textile companies are acquiring innovative nanofiber startups to integrate proprietary weaving technologies into their product lines. This trend is exemplified by recent acquisitions in the filtration and medical device sectors, where nanofiber-enabled products offer significant performance advantages. Strategic M&A activity is often motivated by the desire to secure intellectual property, accelerate time-to-market, and expand into new application domains.

Government initiatives play a pivotal role in fostering the growth of nanofiber weaving technologies. In 2025, agencies such as the U.S. Department of Energy and the European Commission have launched targeted funding programs to support research, pilot-scale manufacturing, and commercialization efforts. These initiatives often prioritize projects with clear environmental or societal benefits, such as advanced air and water filtration or next-generation medical textiles. Additionally, public-private partnerships and innovation clusters are being established to bridge the gap between academic research and industrial deployment.

Overall, the convergence of venture capital, M&A, and government support is accelerating the development and adoption of nanofiber weaving technologies. As the ecosystem matures, stakeholders are increasingly focused on scaling production, reducing costs, and demonstrating real-world impact, setting the stage for broader market penetration in the coming years.

Challenges & Barriers: Technical, Regulatory, and Supply Chain Considerations

Nanofiber weaving technologies, while promising for applications in filtration, medical textiles, and advanced composites, face several significant challenges and barriers as the field advances into 2025. These obstacles span technical, regulatory, and supply chain domains, each presenting unique hurdles to widespread adoption and commercialization.

Technical Challenges: The production of nanofibers with consistent diameter, alignment, and mechanical properties remains a core technical challenge. Techniques such as electrospinning and melt-blowing require precise control over environmental conditions and process parameters to ensure uniformity and scalability. Integrating nanofibers into traditional weaving or knitting processes is also complex, as their small diameter and high surface area can lead to entanglement, breakage, or poor adhesion with other fibers. Furthermore, upscaling laboratory methods to industrial-scale manufacturing without compromising fiber quality or throughput is an ongoing issue for manufacturers such as Freudenberg Group and Auburn Manufacturing, Inc..

Regulatory Barriers: The regulatory landscape for nanofiber-based products is still evolving. Agencies such as the U.S. Food and Drug Administration (FDA) and the European Commission require rigorous safety and efficacy data, especially for medical and food-contact applications. The lack of standardized testing protocols for nanomaterials complicates the approval process, leading to delays and increased costs. Additionally, concerns about the environmental and health impacts of nanofiber production and disposal necessitate comprehensive risk assessments and compliance with emerging regulations.

Supply Chain Considerations: The supply chain for nanofiber weaving technologies is not yet fully mature. Sourcing high-purity polymers and specialized equipment can be challenging, with limited suppliers and long lead times. Companies such as Elmarco s.r.o. and Fitesa are working to expand capacity, but fluctuations in raw material availability and geopolitical factors can disrupt production. Furthermore, the need for skilled technicians and engineers to operate and maintain advanced weaving machinery adds another layer of complexity to scaling operations.

Addressing these challenges will require coordinated efforts among manufacturers, regulatory bodies, and research institutions to develop robust standards, streamline approval processes, and build resilient supply chains for the future of nanofiber weaving technologies.

Future Outlook: Disruptive Opportunities and Strategic Recommendations for Stakeholders

The future of nanofiber weaving technologies is poised for significant disruption and opportunity, driven by advances in material science, automation, and cross-industry collaboration. As the demand for high-performance, lightweight, and multifunctional materials intensifies across sectors such as healthcare, filtration, energy, and textiles, nanofiber weaving is expected to play a pivotal role in next-generation product development.

One of the most promising disruptive opportunities lies in the integration of artificial intelligence and machine learning with automated weaving systems. These technologies can optimize fiber alignment, defect detection, and process parameters in real time, leading to higher yields and consistent quality. Companies like DuPont and Toray Industries, Inc. are already investing in smart manufacturing platforms that could accelerate the commercialization of advanced nanofiber fabrics.

Another area of innovation is the development of bio-based and biodegradable nanofibers, which address growing environmental concerns. Strategic partnerships between material innovators and end-use industries—such as those fostered by Freudenberg Group in filtration and medical applications—are expected to yield sustainable alternatives without compromising performance.

For stakeholders, several strategic recommendations emerge:

- Invest in R&D and Talent: Continuous investment in research and the recruitment of interdisciplinary talent will be crucial to stay ahead in the rapidly evolving nanofiber landscape.

- Foster Cross-Sector Collaboration: Engaging with partners across the value chain—from raw material suppliers to end-users—can accelerate innovation and open new markets.

- Adopt Digitalization: Embracing digital twins, predictive analytics, and automation will enhance process efficiency and product customization.

- Prioritize Sustainability: Developing eco-friendly nanofiber solutions and transparent supply chains will be increasingly important for regulatory compliance and consumer trust.

Looking ahead to 2025 and beyond, the convergence of advanced manufacturing, digital technologies, and sustainability imperatives will define the competitive landscape for nanofiber weaving. Stakeholders who proactively adapt to these trends and invest in disruptive capabilities will be best positioned to capture emerging opportunities and drive industry transformation.

Sources & References

- Freudenberg Group

- Ahlstrom

- Hollingsworth & Vose

- Teijin Limited

- DuPont

- Medtronic

- Donaldson Company, Inc.

- Auburn Manufacturing, Inc.

- Nanofiber Labs

- Association of the Nonwoven Fabrics Industry (INDA)

- Textile Institute

- Elmarco

- Stäubli International AG

- Institut für Textiltechnik of RWTH Aachen University

- Uster Technologies AG

- AAF International

- Smith+Nephew

- NASA

- Oak Ridge National Laboratory

- Fraunhofer Society

- European Commission

- Fitesa